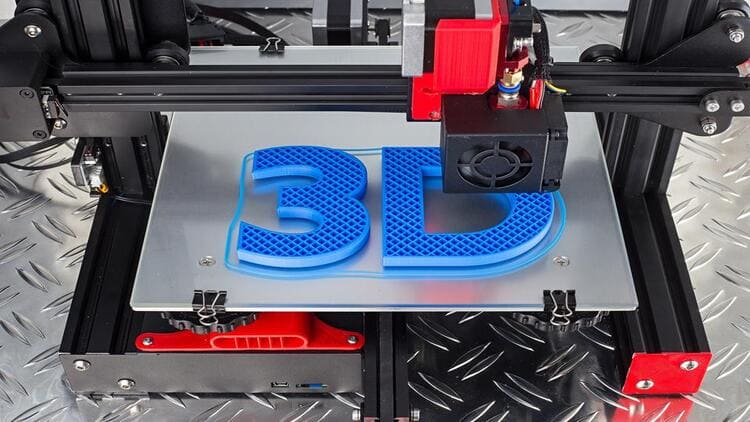

3D printing has been a major technological advance in the last decade or so. A new era of innovation will be unleashed in the same manner that computers and the Internet have advanced, and 3D printing service is no exception. Currently, several scientists have recognized the potential of 3D devices and are working hard to completely examine and make use of this brand-new technological advancement. Some incredible 3D printed objects are showcased in this section.

There are seven major uses for 3D printing technology.

Motorsports

Using a 3D printer, a college student in China built a racing automobile. With a top speed of 100 miles per hour and a weight of 220 kilograms, this car is extremely light. However, the cost of production is extremely high. It is the student’s expectation that the price of this material will be reduced in order to reduce the production costs significantly. Carbon fiber and plastic are used in the construction of the vehicle. When using a 3D printer, you don’t have to worry about installing a lot of small parts in order to construct complex parts. Students will be able to complete repairs in a fraction of the time they would have otherwise needed.

Personalize your own Star Wars memorabilia

Personalized Star Wars projects were made available to fans after Disney bought the franchise in 2012. Visitors at Disneyland can dress up as Stormtroopers or Han Solo, for example. 3D printing service will be used to create an accurate model of the customer’s face, which will be 7 inches long. The entire operation costs roughly $100.

Of course, this kind of technology has been employed in video games for a long time. In the game, they allow players to change their appearance to fit their character’s character Such services are even provided by other businesses. It’s possible for them to develop superheroes for consumers based on the images they receive from them.

A bicycle made of nylon.

“Airbike” was invented by Eads in order to demonstrate its unique printing process. Nylon layers are heated with a strong laser to form equivalent layers, allowing them to be piled layer by layer to build a completely functional completed product, including pedals and chains. It’s mainly because of the lighter weight of nylon bicycles, but the same level of strength as steel, that Eads believes nylon bicycles outperform traditional bicycles. In addition, the nylon bicycle’s manufacturing technique is more environmentally friendly than that of traditional bicycle manufacture.

A few helpful resources

Customized tools are being created with 3D printers by some manufacturers. From the most basic wrenches and hammers to those necessary for working in extreme conditions, this category of the tool has it all. They even think users may be able to design their own tools in the future.

Additionally, STRATASYS has developed a cordless drill that incorporates a range of polymers. The body and drill bit are constructed of soft materials, which create a robust plastic body. The benefit of this is that replacement components may be printed in-house rather than requiring a new batch to be shipped in from the manufacturer.

Batteries and generators are the fifth items on the list.

Electronic devices have become ubiquitous in our modern world, which would be unimaginable without power. Every day, people should avoid carrying about their own electronic device batteries. With the help of a 3D printer, Erichsen came up with a solution: a hand-powered generator. When running at its maximum speed of 4000 rpm, the generator produces enough power to run portable electronics like cell phones.

Lithium-ion batteries could benefit greatly if they could be manufactured using 3D printing technology. This battery’s architecture is more energy-efficient than previous batteries, and it can hold more power.

The sixth robot is referred to here.

Robots are extremely beneficial and handy. They may be able to assist individuals in doing certain tasks or resolving certain issues. Occasionally, they’ll make friends with people and join in on their antics. Numerous robots have been developed to do various tasks as 3D printing technology became more extensively used.

Dimensional printing (additive manufacturing)

Has anyone tried to make their own 3-d Printer? Currently, 3D printing researchers are conducting research on this topic. Like Russian dolls, the goal of this open-source project is to create an autonomous 3D printing device. An open-source project allows anyone who wants to help attain this aim to do so. The project has delivered four different printing equipment models thus far. There is now a belief that a 3D printer can make a second copy of practically all of the parts required, and can print infinitely.